Carpet Manufactured using sustainable energy

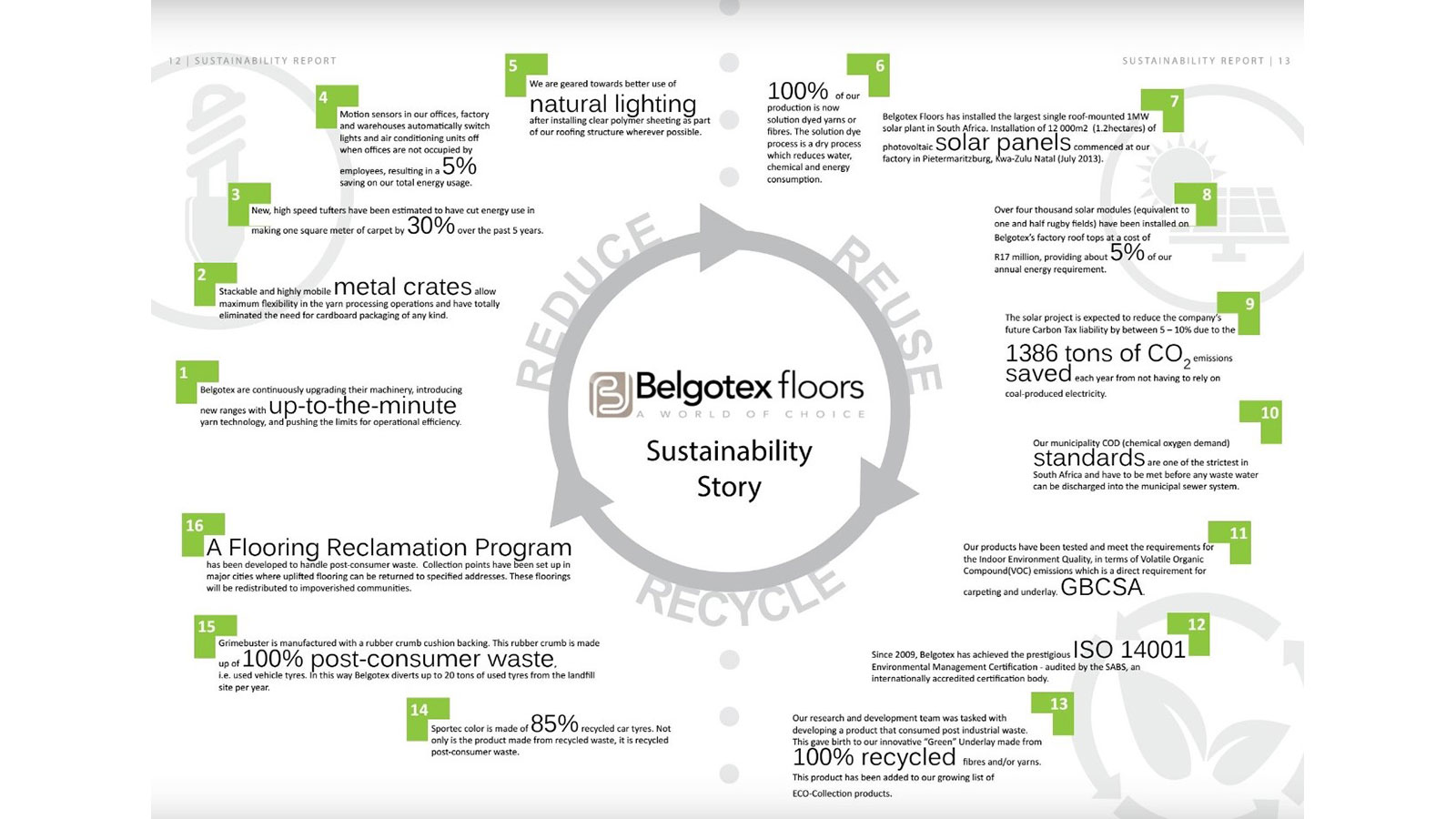

Our flooring partner Belgotex’s Eco-Pillars drive their multi-dimensional, long-term operational plans. It challenges them to ask more of themselves and less of the planet in all that they do. Below is a synopsis of the 3 eco pillars that they have been practicing, out of which manufacturing of carpet using solar power is just one of them

Water Management.

Embracing change in our traditional manufacturing processes and repurposing harvested rainwater has reduced water consumption by 35 - 45% since 2015.

Waste management.

We have placed waste management high on our agenda, with investments in excess of R5 million that have enabled Belgotex to reduce material waste rates to almost zero.

Energy Conservation.

Belgotex has invested over R20 million to date in solar power, resource efficiency and plant upgrades in an active drive to offset CO2 emissions and save energy.

Since the start of their green journey in 1991, they have constantly pushed the limits for operational efficiency, seeking out ecologically sustainable manufacturing methods and developing eco-friendly products. This has eventually led to Belgotex being the proud recipient of South Africa’s first Custom Industrial 6 Green Star rating. This 6 Star certification recognises “World Leadership” of their Pietermaritzburg-based factory for their sustainability practices in all aspects of plant and carpet manufacturing operations

As the first South African flooring manufacturer to earn the coveted Global GreenTag eco-label certification, they have achieved another significant sustainability milestone. This internationally recognised “Level A” Global GreenTag certification – called GreenRate™ – maximises their products’ eligibility to achieve 100% of the available credit points across all South Africa’s Green Building Council (GBCSA) rating tools. The stringent assessment process has equipped them to develop holistically and entrench sustainability across their value chain.